Smart Laundry Tower

Master’s Project | Integrated Innovation

“From Dirty to Dressed in 20 Minutes or Less”

Designing an AI-powered laundry system that replaces washers and dryers with parallel processing technology.

The Challenge

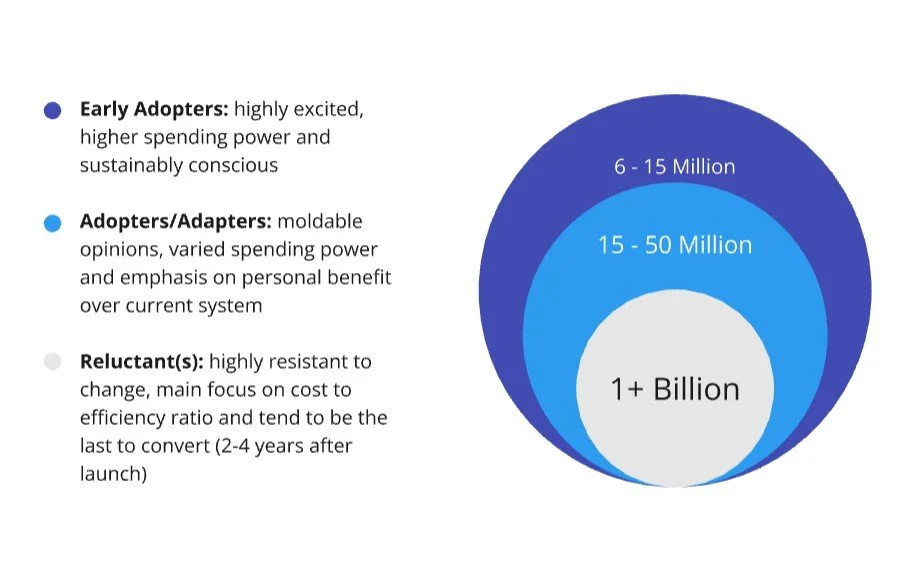

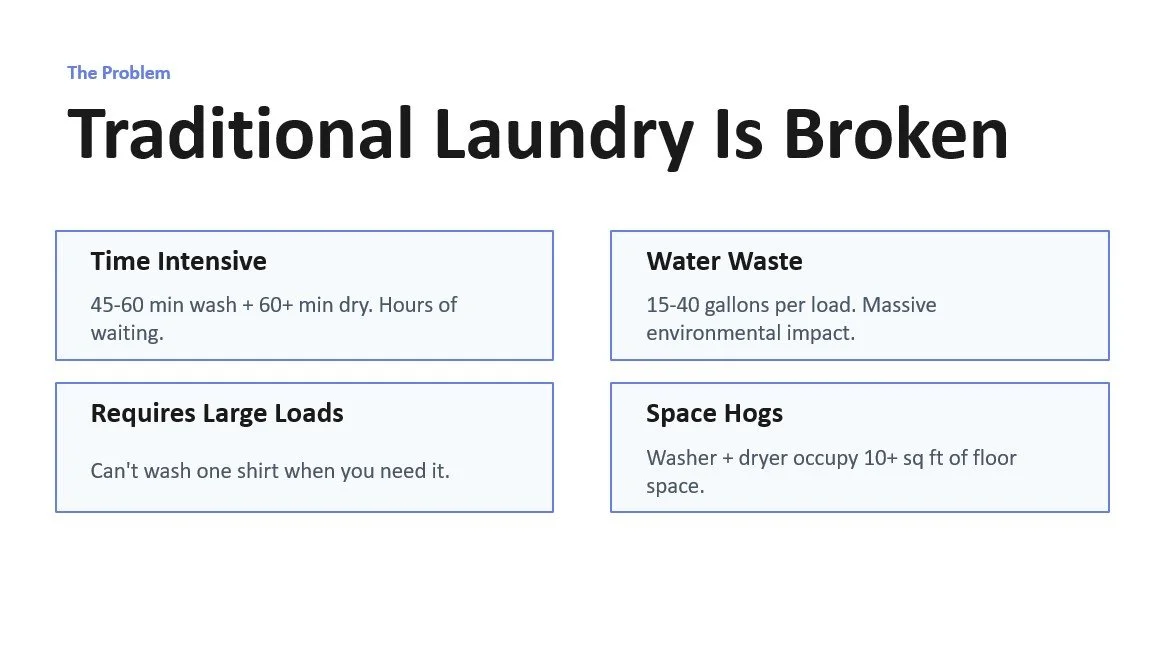

Traditional laundry is time-intensive, water-wasteful, and requires large load processing. How might we re-imagine laundry for modern, on-demand, sustainable lifestyles?

70% Faster than traditional

98% Less water

3x Parallel processing

$50B+ Market Opportunity

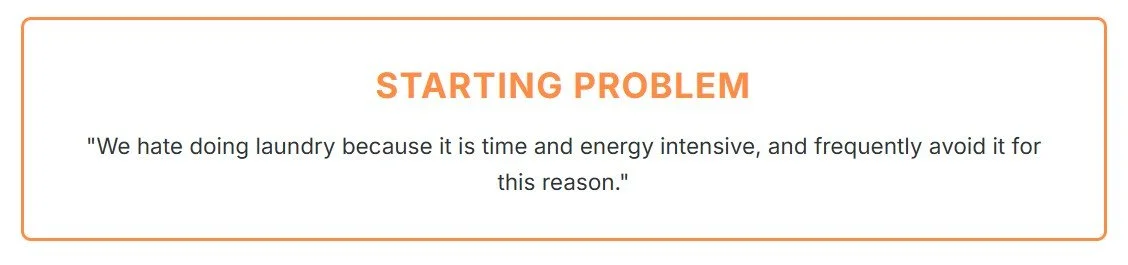

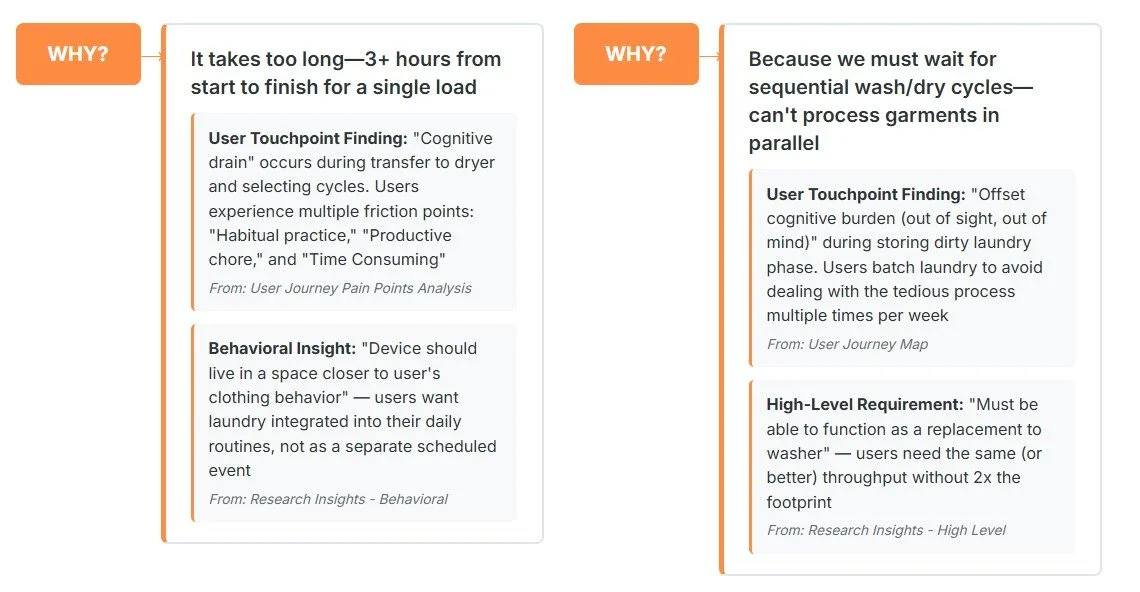

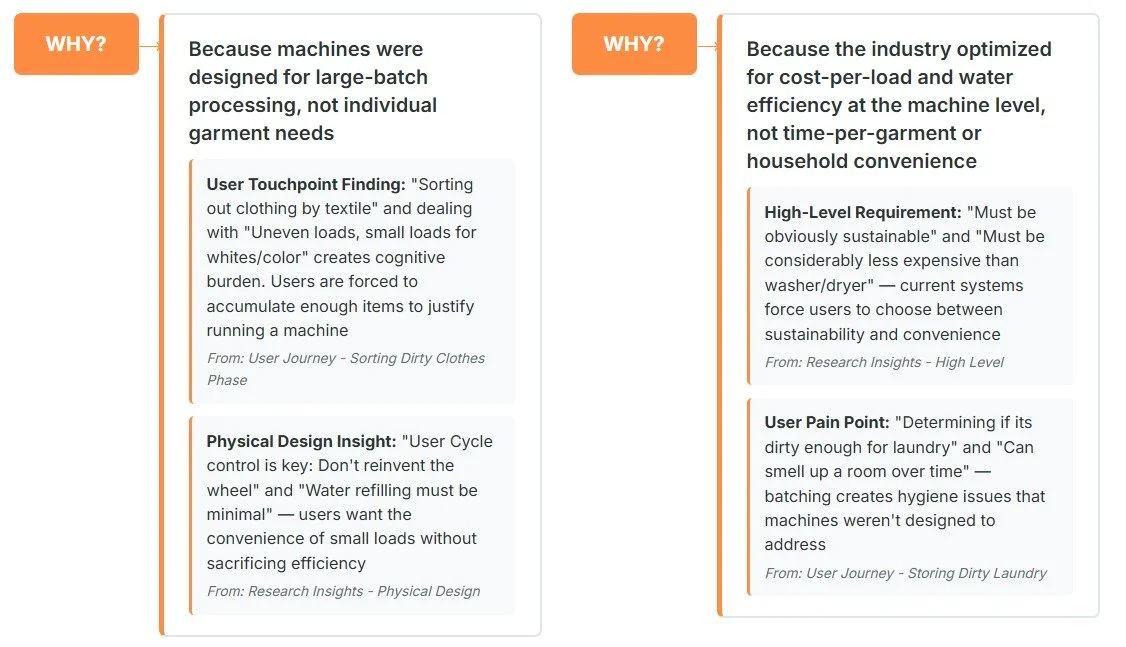

Understanding the Problem

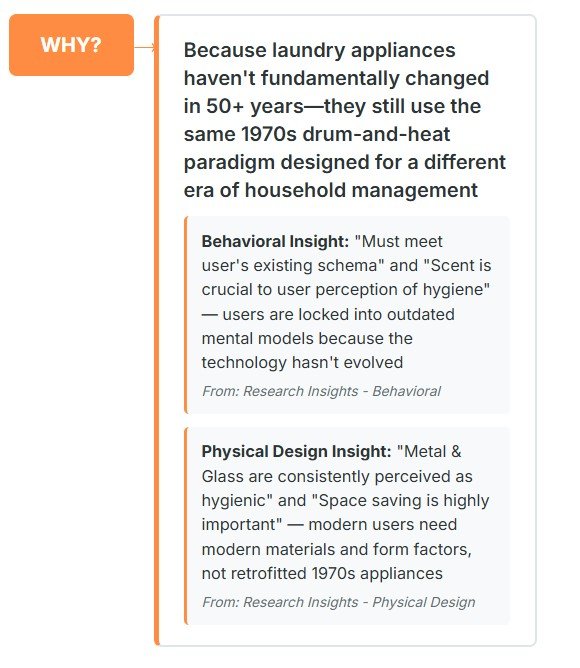

Root Cause Analysis:

Why Laundry is Broken

Uncovering the fundamental design flaws in traditional laundry systems through research-driven enquiry.

The User Experience Reality

“We don’t always have full loads to wash. We have coffee-stained shirts before meetings, gym clothes after workouts, and gross kids’ outfits after trips to the playground..” Interviewee

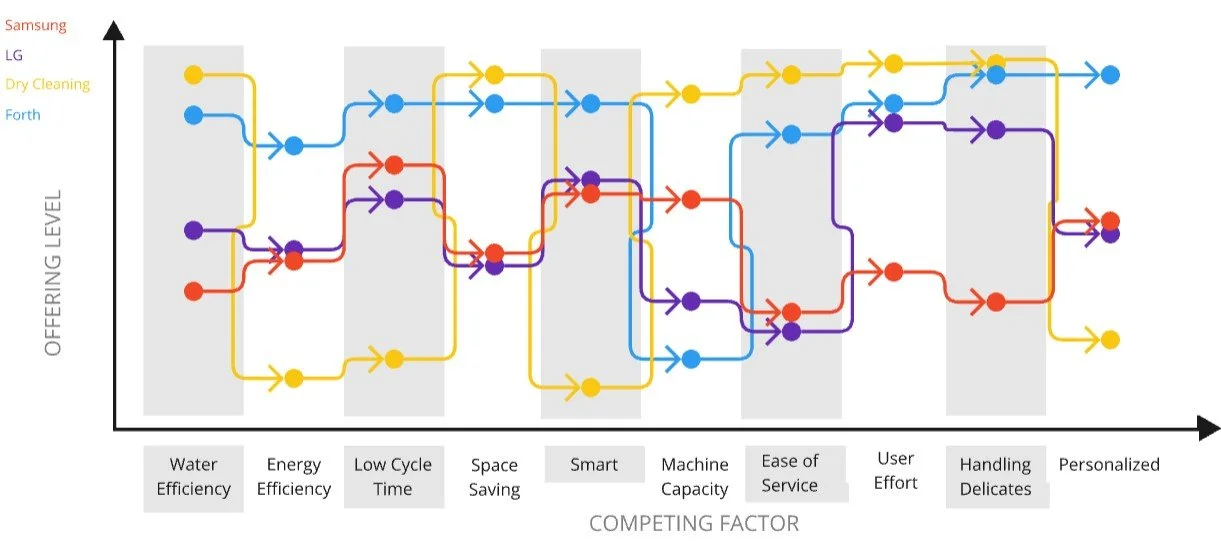

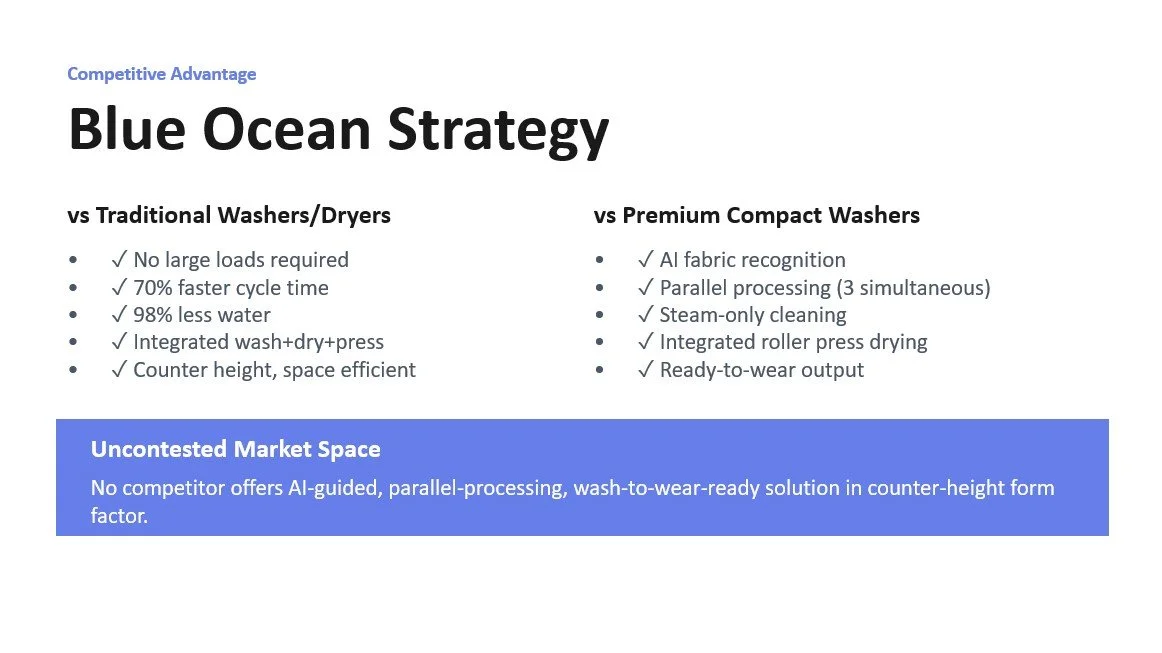

Identifying Uncontested Space

The Blue Ocean Strategy Canvas maps Smart Laundry Tower against traditional appliances (Samsung, LG) and premium services across 10 competing factors. While incumbents optimize for batch capacity and dry cleaners excel at garment care, Smart Laundry Tower occupies uncontested market space: 20-minute wash-to-wear cycles with 98% less water in a counter-height form factor. The strategic insight: stop competing on capacity, start winning on speed and convenience.

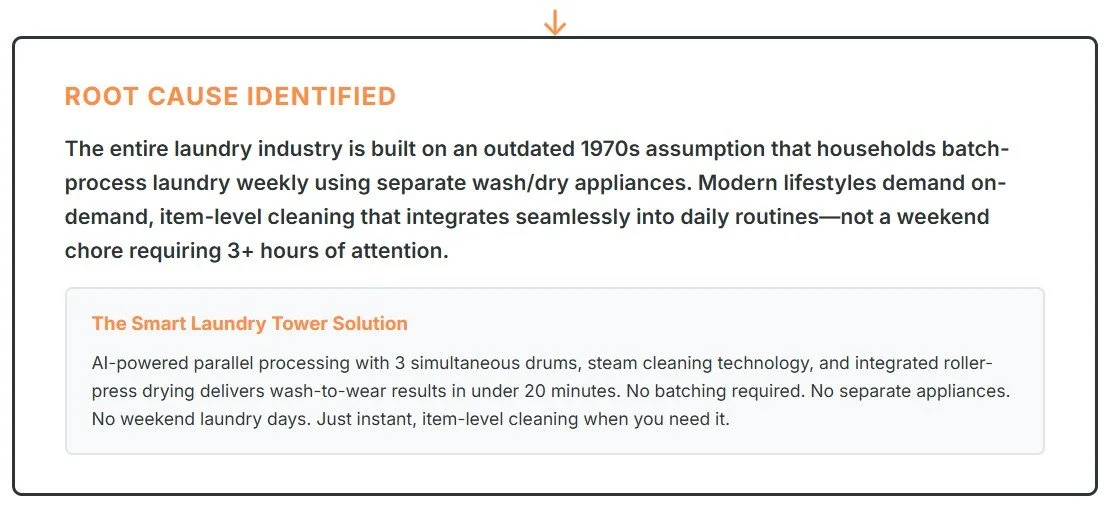

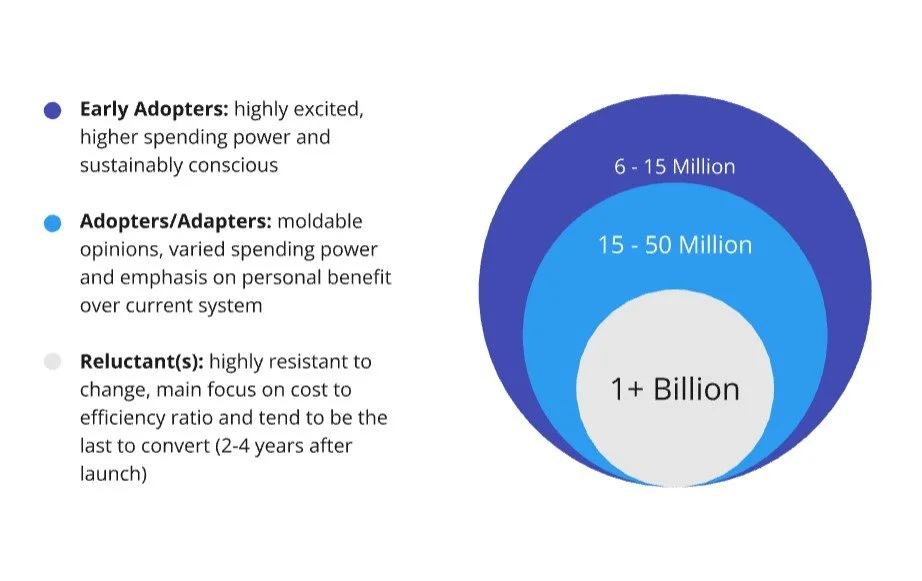

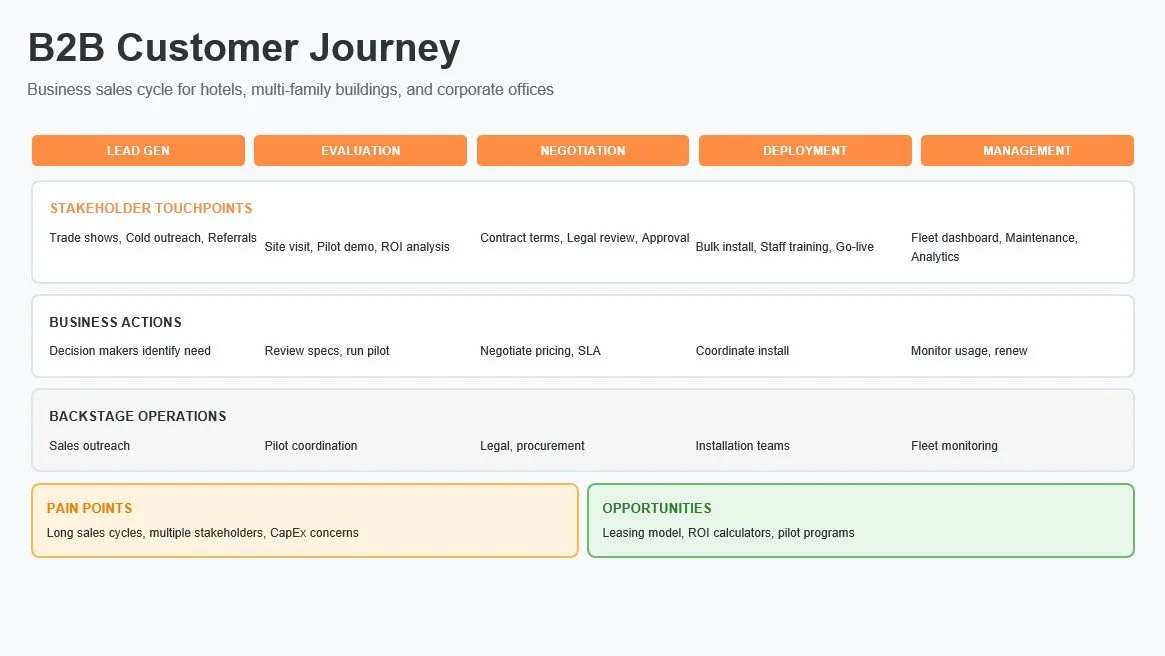

Market Segmentation

The $50B+ market breaks into three behavioral segments: Early Adopters excited by sustainability and innovation (6-15M), Adapters prioritizing personal benefit over system change (15-50M), and cost-focused Reluctants requiring 2-4 years of market proof (1B+ global).

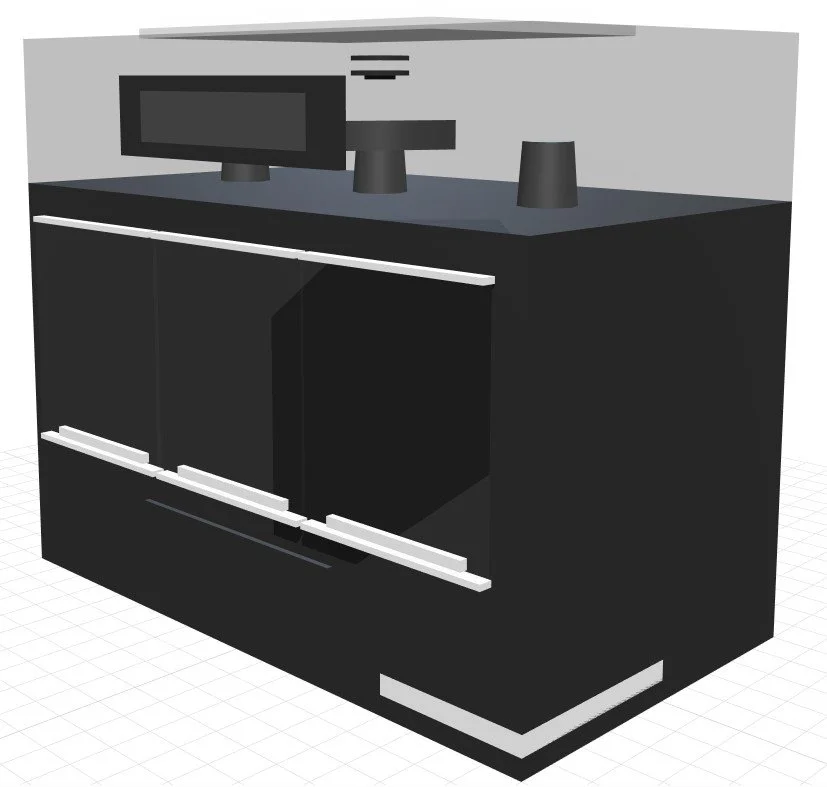

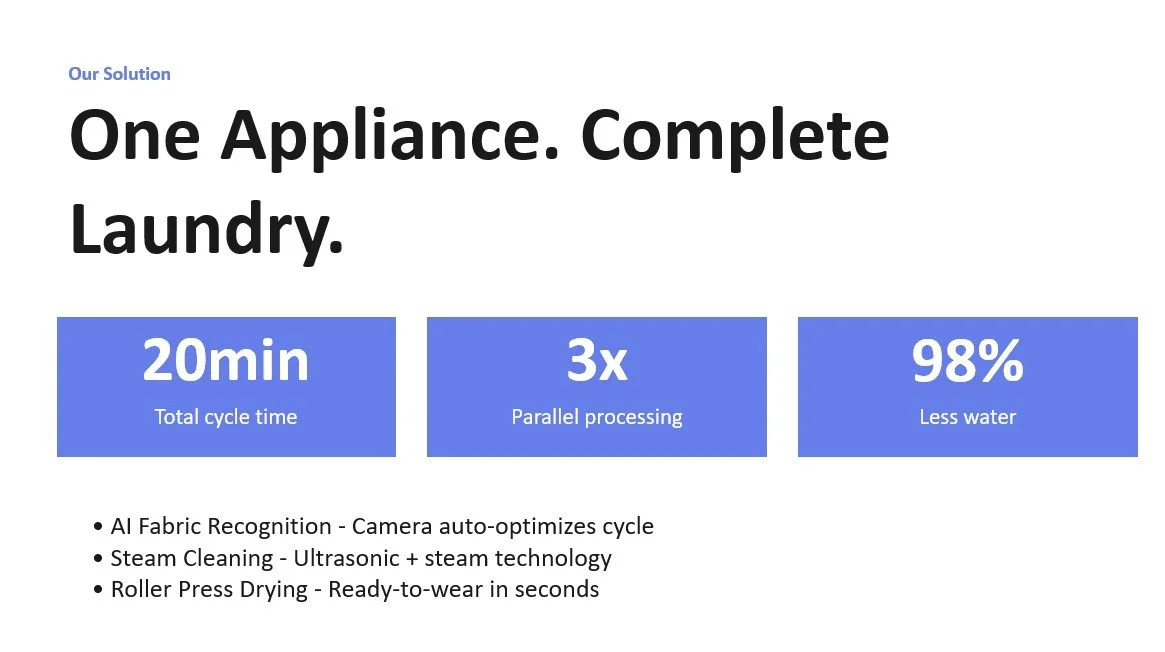

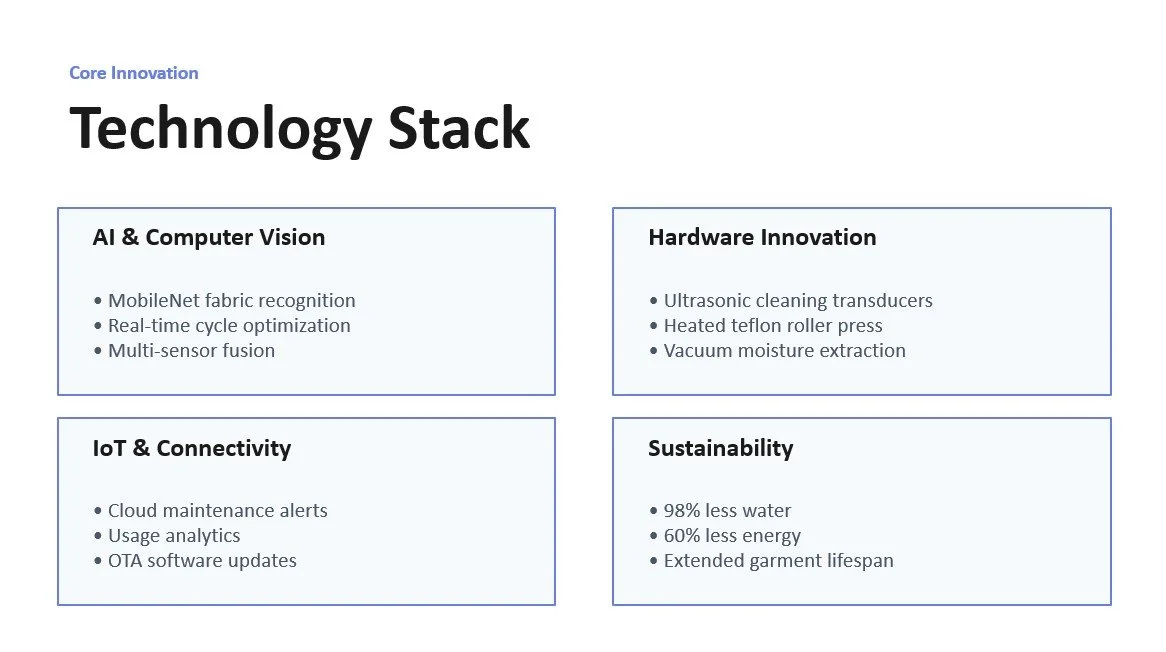

20 Min. Dirty to Dressed

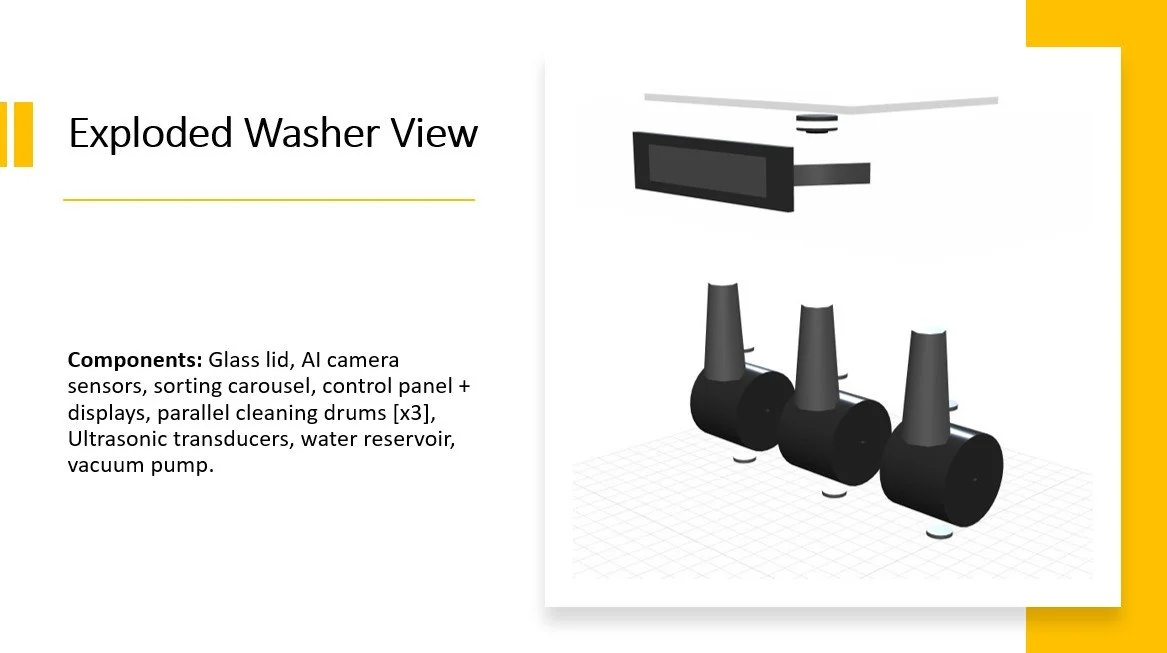

What if laundry weren’t a 3-hour weekend chore but a 20-minute on-demand service? The Smart Laundry Tower combines AI fabric recognition, parallel processing across three drums, and integrated steam-to-press drying in a counter-height appliance that uses 98% less water than traditional washers.

01

20 Minute Cycle Time

02

3x Parallel Processing

03

98% Less Water

The Iterative Process

01

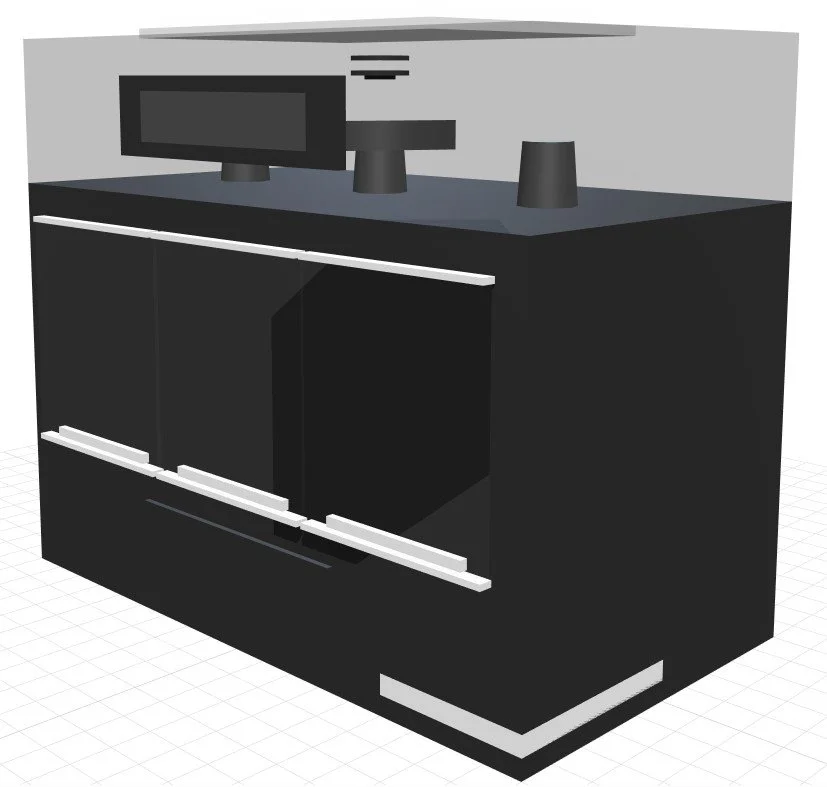

Initial Concept: Vertical tower.

Specs: 60”H x 24”W, 3 drums stacked vertically.

Rationale: Maximize space efficiency through vertical stacking.

Issues: Too tall for most spaces, stability concerns, fights gravity, poor accessibility.

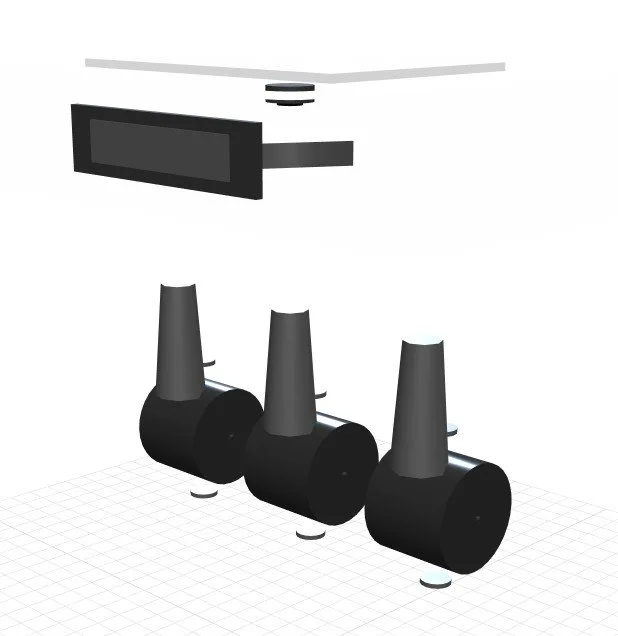

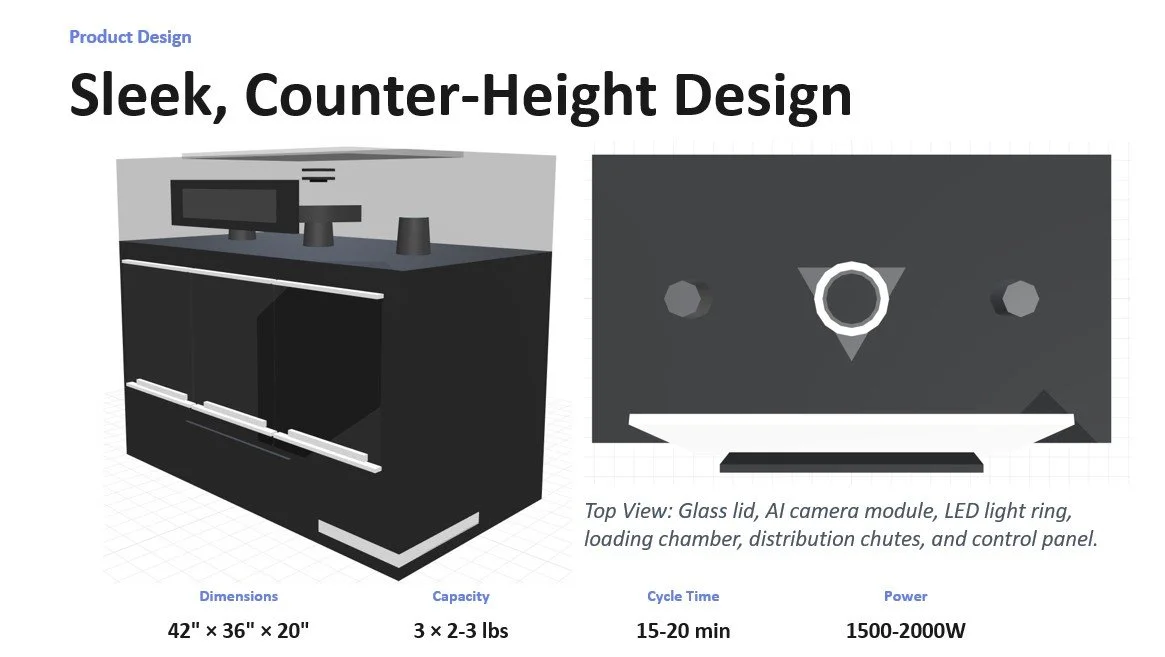

03

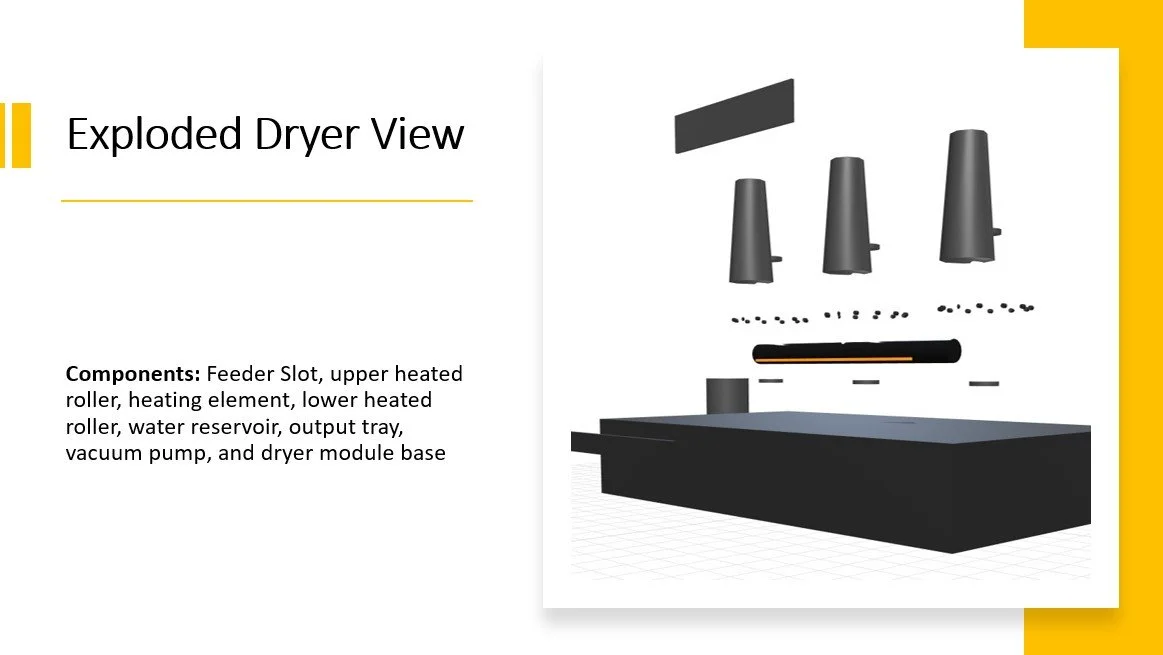

Breakthrough: Integrated Drying

Additions: Heat roller press + Vacuum extraction

Impact: True washer/dryer replacement, complete solution [wash + dry + press], Ready-to-wear output, 60% less energy than tumble dryers, and final height: 42” [still counter height]

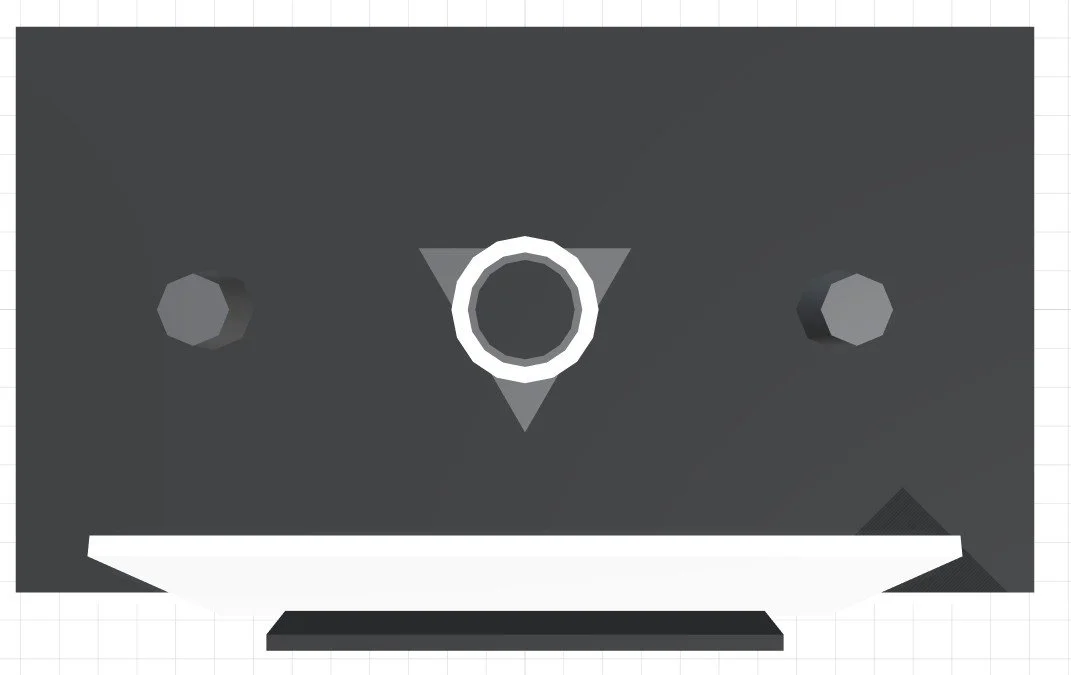

Pivot: Horizontal Layout

New Specs: 36”H x 36”W x 20”D, drums side-by-side

Key Insights: Works with physics, counter height, natural top-loading, improved stability, and better accessibility.

Cons: Doesn’t offer original drying solution

02

Key Insight

“As someone new to the engineering process, the most valuable lesson I learned was when to pivot. I was reminded that great design means having the courage to abandon my first idea when evidence suggested a better path.”

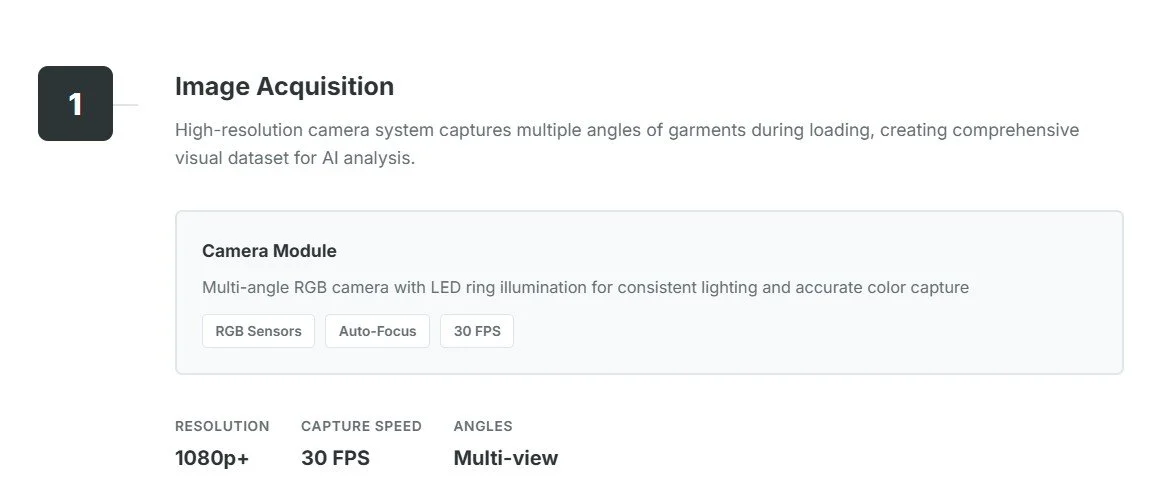

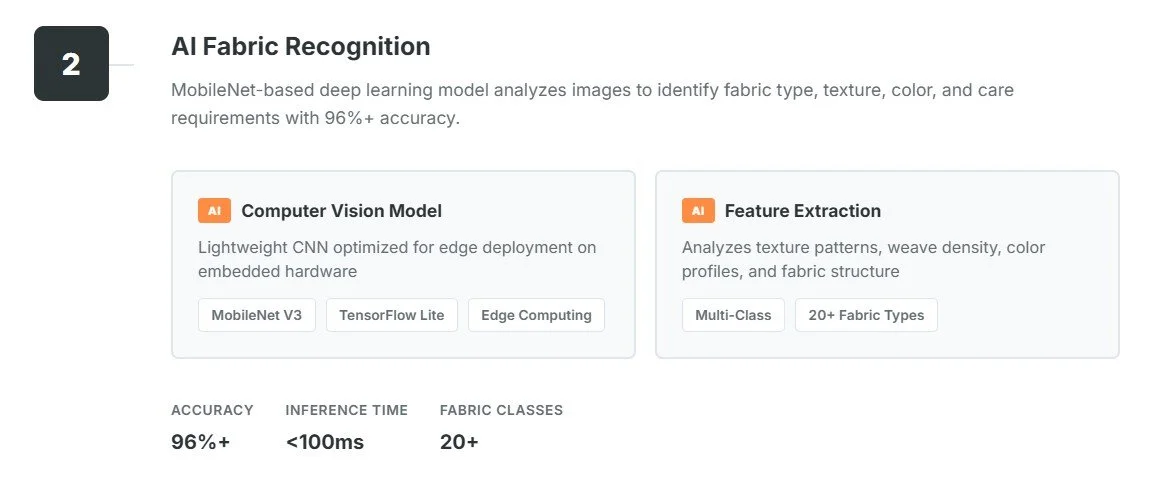

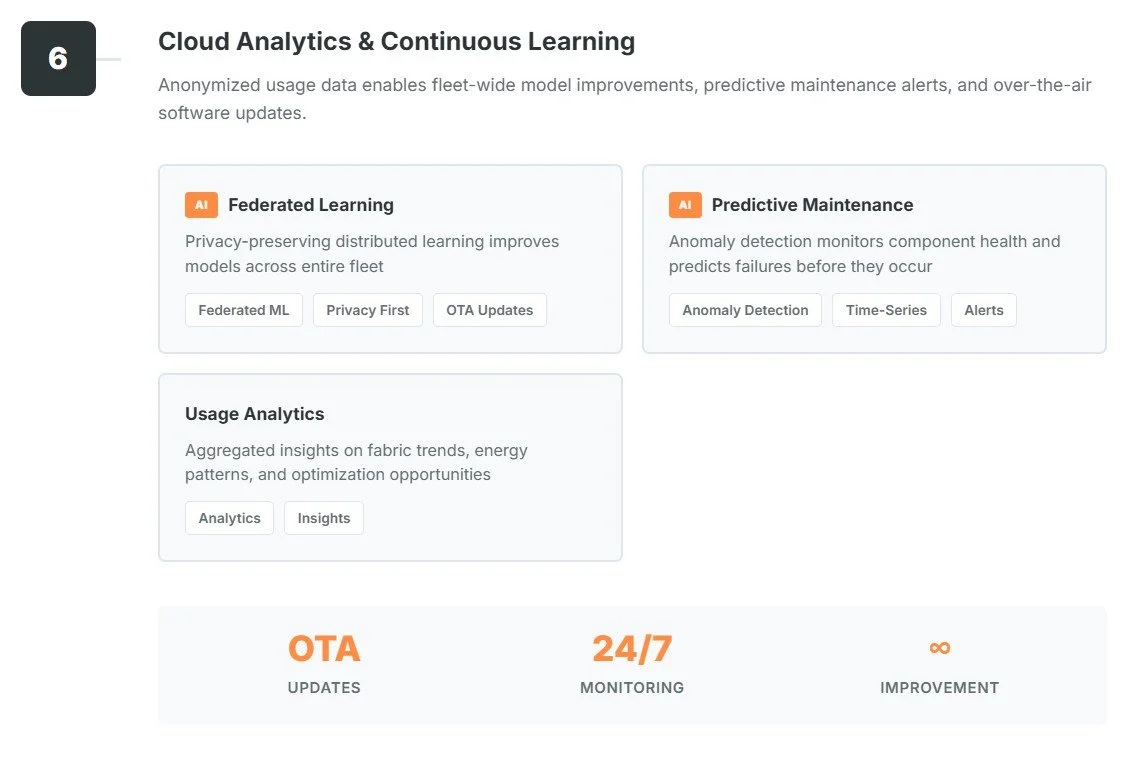

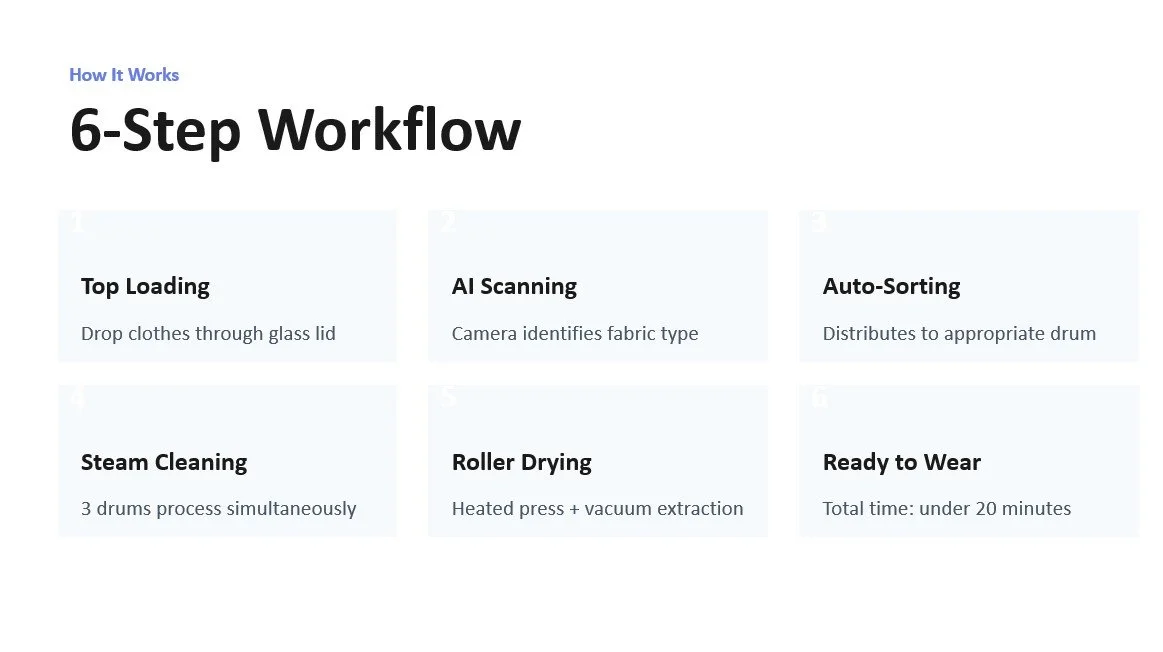

Technical Architecture

AI Process Flow

Driven by curiosity and built on purpose, this is where bold thinking meets thoughtful execution. Let’s create something meaningful together.

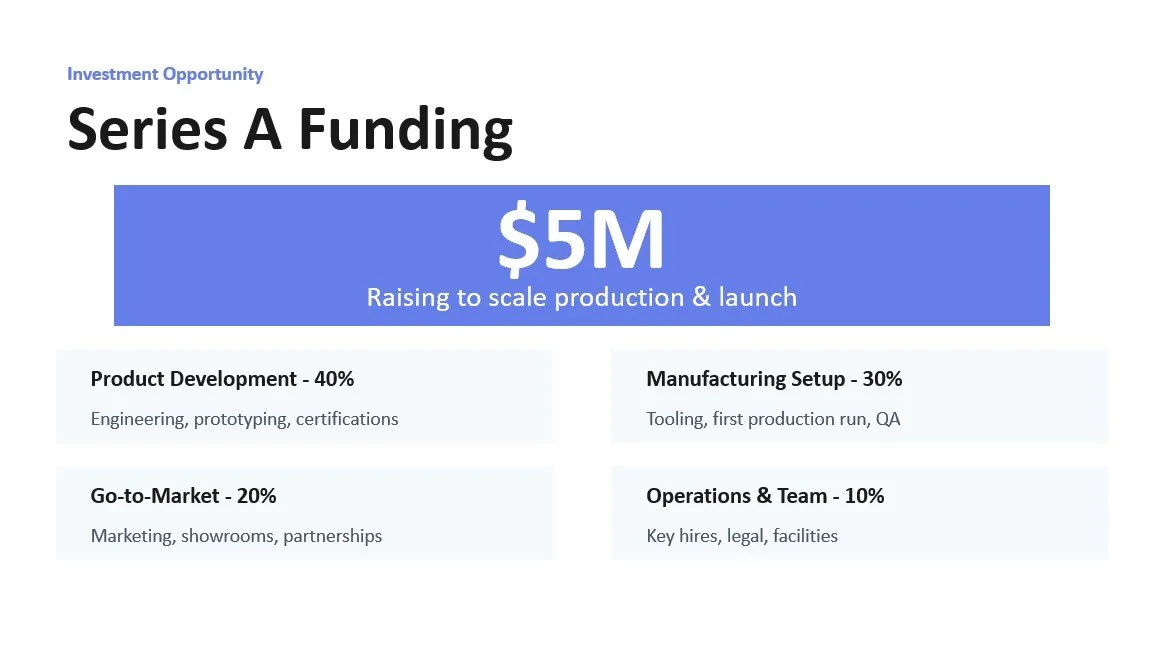

The Pitch

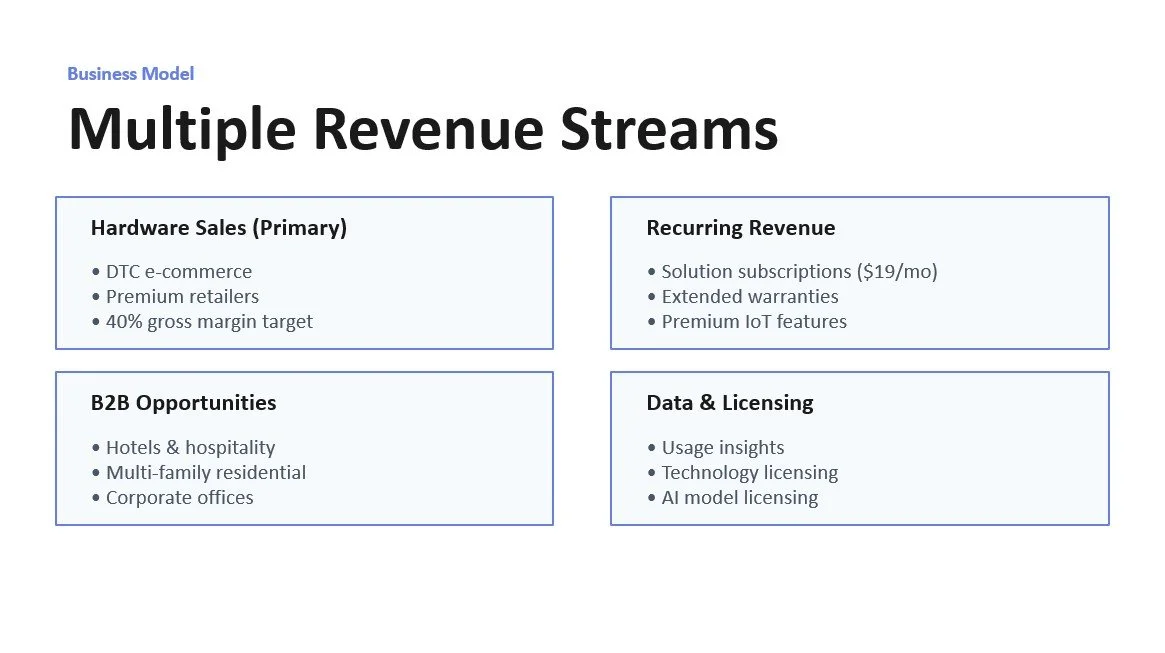

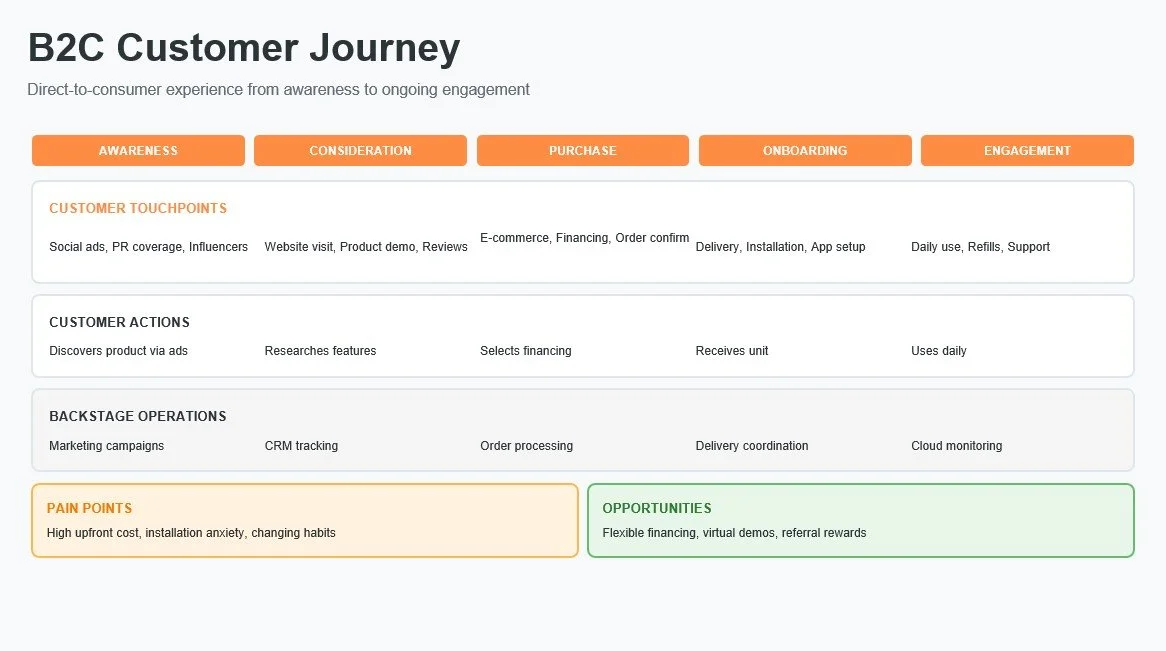

The Service Plan